Aug 26, 2025

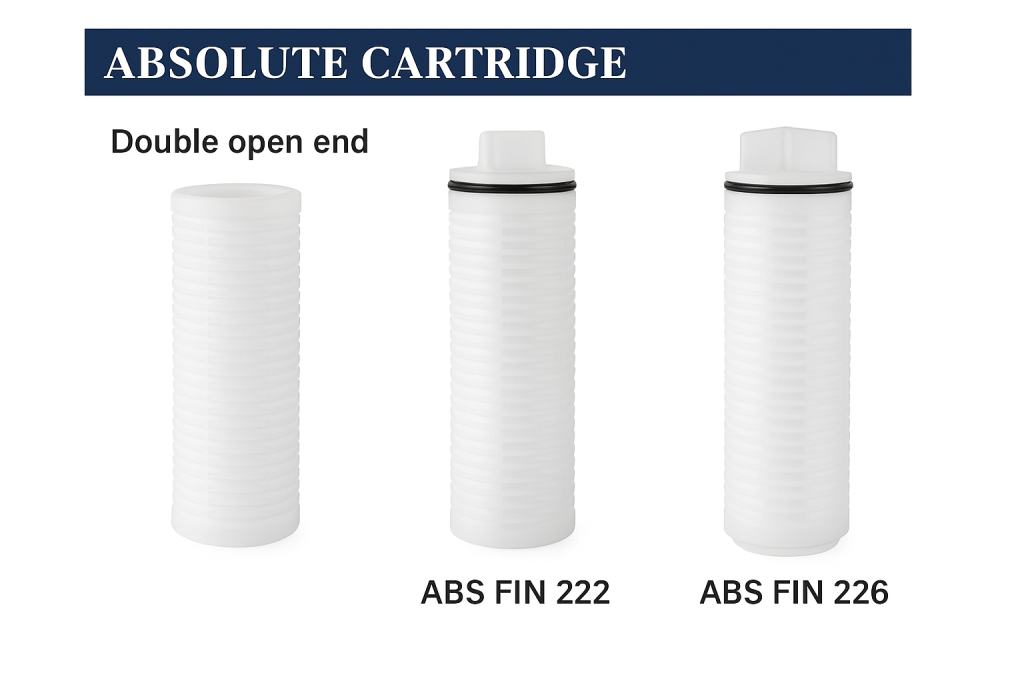

Understanding Absolute Cartridge Filters: DOE, FIN 222, and FIN 226

Filtration plays a critical role across industries such as pharmaceuticals, food and beverage, water treatment, and electronics. To ensure product quality and safety, companies rely on absolute-rated filter cartridges, which guarantee consistent removal of particles at a specified micron rating. Unlike nominal filters that capture “most” particles, absolute filters provide precise and validated filtration, making them ideal for critical applications.

What is an Absolute Cartridge Filter?

An absolute cartridge filter is a pleated or depth-type cartridge designed to trap contaminants at an exact pore size. For example, a 0.22 µm absolute filter is validated to remove bacteria, making it suitable for sterile filtration. These cartridges are housed in filter housings, where liquid passes through the media, and unwanted particles are retained.

Common Configurations

1. Double Open End (DOE)

- Design: Both ends of the filter are open, with no O-rings.

- Application: Typically used in general water purification, food and beverage pre-filtration, and industrial applications.

- Advantages: Simple design, easy to install, and compatible with standard housings.

2. ABS FIN 222

- Design: Single Open End (SOE) cartridge with a fin-style closed top and a 222 O-ring fitting at the bottom.

- Application: Commonly used in pharmaceutical and biotech industries where secure sealing is critical to avoid bypass.

- Advantages: Provides a reliable seal, reduces risk of leakage, and ensures compliance in sanitary environments.

3. ABS FIN 226

- Design: Similar to FIN 222 but uses a 226 O-ring fitting, often with a bayonet lock to prevent movement under pressure.

- Application: Widely used in sterile filtration, critical water systems, and high-purity chemical processing.

- Advantages: Offers maximum sealing integrity, especially in high-pressure or high-temperature processes.

How These Filters Are Used in Practice

- Water Treatment

- DOE cartridges are often installed in multi-cartridge housings to remove sediment, rust, or microorganisms from municipal or process water.

- In ultrapure water systems, FIN 222 or FIN 226 filters are preferred due to their sanitary design and leak-proof sealing.

- Pharmaceuticals & Biotechnology

- 0.22 µm absolute-rated FIN 222 or FIN 226 cartridges are validated for sterile filtration of injectable drugs, culture media, and biological products.

- Their O-ring design ensures no contamination bypasses the filter.

- Food & Beverage

- Used for clarification and microbial stabilization in beer, wine, bottled water, and dairy products.

- DOE filters may be used in pre-filtration, while FIN 222/226 cartridges handle critical microbial removal steps.

- Electronics & Chemicals

- High-purity chemical filtration requires FIN 226 cartridges for strong sealing to prevent leakage in corrosive or high-value fluids.

- Ensures particle-free solvents and process fluids for semiconductor manufacturing.

Why the Correct End-Connection Matters

Choosing the right connection (DOE, 222, or 226) depends on the housing design and application.

- DOE → general use, cost-effective.

- FIN 222 → sanitary applications requiring secure sealing.

- FIN 226 → critical processes with higher sealing and locking requirements.

✅ In summary:

Absolute cartridge filters are essential for achieving high-quality, contamination-free liquids. Whether using DOE for industrial water treatment, FIN 222 for pharmaceutical sterile filtration, or FIN 226 for high-pressure sanitary applications, these filters protect processes, products, and ultimately, consumers.