Jul 29, 2025

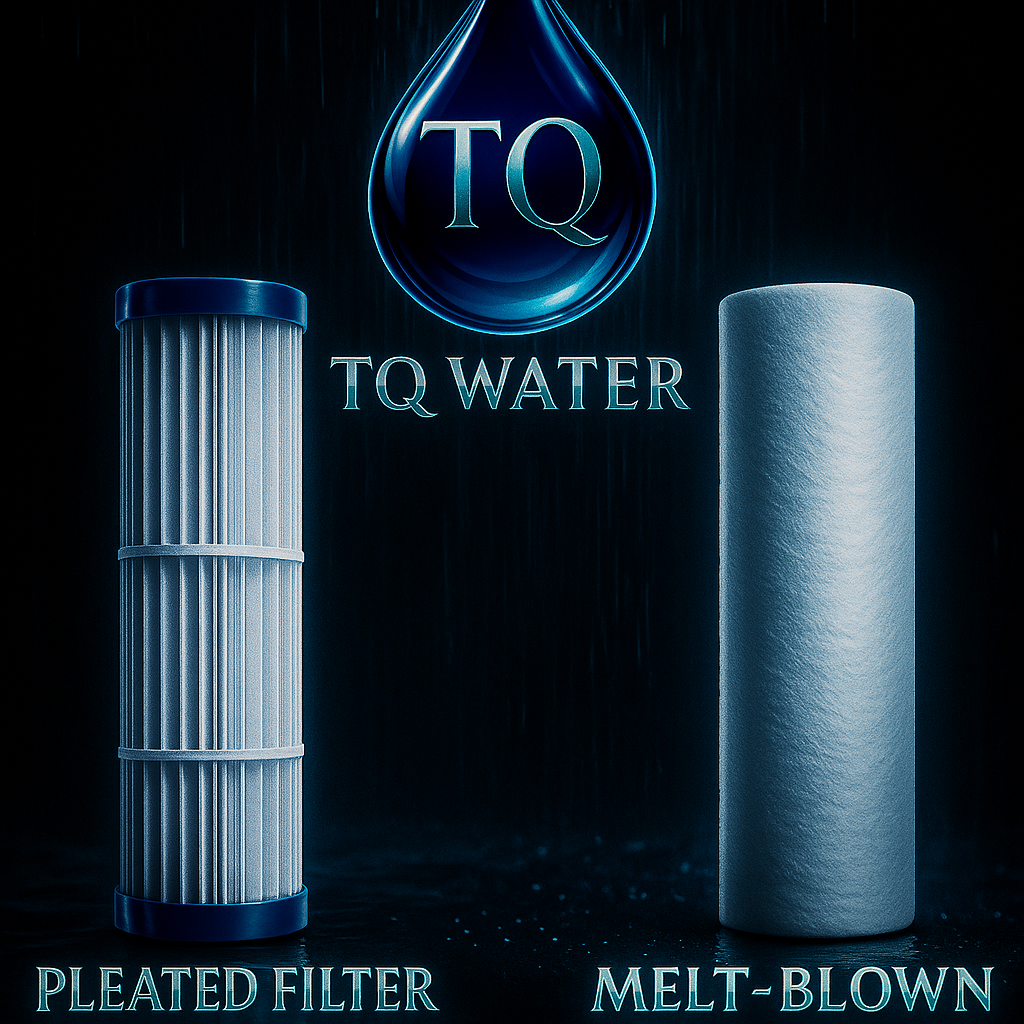

Pleated Filter vs. Melt-Blown Filter: Which One Is Right for Your Filtration Needs?

When it comes to water filtration—whether in industrial systems or residential setups—the right filter can make all the difference. Two of the most common types of filtration media are Pleated Filter Cartridges and Melt-Blown (Polypropylene or PP) Filters. Each type offers unique advantages and is suited for specific applications. Understanding the differences between these filters will help you make a more informed decision based on flow rate, particle retention, cost, and maintenance.

What is a Pleated Filter Cartridge?

Pleated filters are constructed from synthetic media like polypropylene, polyester, or glass fiber, which is folded into pleats to create a larger surface area. This design allows for higher dirt-holding capacity and longer service life. These cartridges are often used in demanding applications where precision and flow rate are critical.

Key Features:

- High filtration efficiency

- Large surface area due to pleated design

- Low initial pressure drop

- Washable and reusable in some models

- Available in a wide range of micron ratings (0.2 µm to 100 µm)

Applications:

- Pharmaceutical manufacturing

- Food and beverage production

- Electronics cooling systems

- RO (Reverse Osmosis) prefiltration

- High-purity water systems

What is a Melt-Blown (PP) Filter Cartridge?

Melt-blown filters are manufactured through a process that extrudes melted polypropylene into a web of fibers, which then form a gradient-density structure. This structure captures particles of varying sizes as the fluid moves from the outer surface inward.

Key Features:

- Depth filtration design

- High dirt-holding capacity

- Cost-effective

- One-time use (not washable)

- Typically available in 1–100 µm ratings

Applications:

- General industrial water filtration

- Residential water systems

- Chemical and solvent filtration

- Prefiltration before finer stages

Side-by-Side Comparison

| Feature | Pleated Filter Cartridge | Melt-Blown (PP) Filter |

|---|---|---|

| Micron Range | 0.2 – 100 µm | 1 – 100 µm |

| Filtration Type | Surface filtration | Depth filtration |

| Material | Polypropylene, Polyester, Glass | Polypropylene (PP) |

| Reusability | Often reusable | Disposable |

| Flow Rate | Higher | Moderate |

| Pressure Drop | Low | Slightly higher |

| Cost | Higher upfront cost | More economical |

| Best For | Precision filtration | General filtration needs |

Which Filter Should You Choose?

- Choose a Pleated Filter Cartridge if your application demands high flow rates, low pressure drops, and precise particle removal. They’re ideal for industries requiring strict contamination control.

- Opt for a Melt-Blown (PP) Filter if you’re looking for a cost-effective, reliable, and easy-to-replace solution for less critical applications or as a prefilter in multi-stage systems.

Final Thoughts

Selecting the correct filter is crucial for system performance, longevity, and cost-effectiveness. Whether you’re managing a residential filtration system or a high-volume industrial plant, understanding the differences between pleated and melt-blown filters ensures clean, safe, and efficient water handling.

More Details💧 Pro Tip: Consider combining both filters in a staged setup—using melt-blown filters for rough filtration and pleated filters for fine polishing—to maximize efficiency and lifespan.